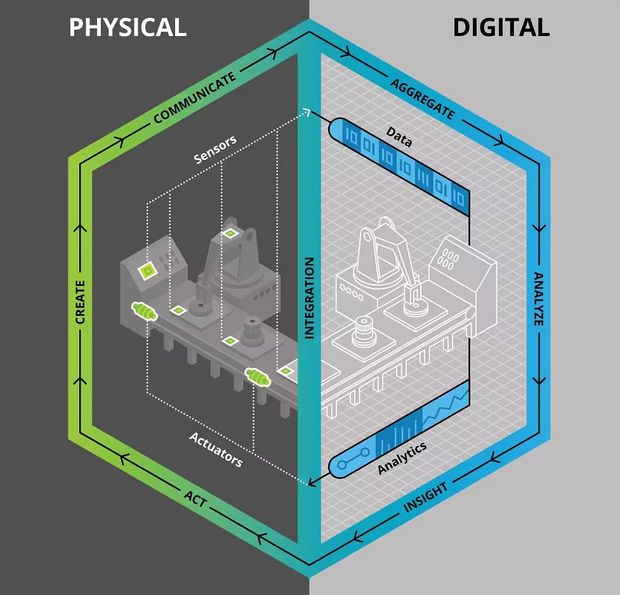

In today’s rapidly evolving technological landscape, the concept of a digital twin has emerged as a game-changer across various industries. A digital twin represents a virtual replica of a physical entity, whether it’s a machine, a process, or even a living organism. What sets it apart is its ability to remain synchronized with its real-world counterpart in real-time, constantly updating its status based on incoming data streams. This symbiotic relationship between the physical and digital realms opens up a world of possibilities, offering valuable insights and predictive capabilities that were once unimaginable.

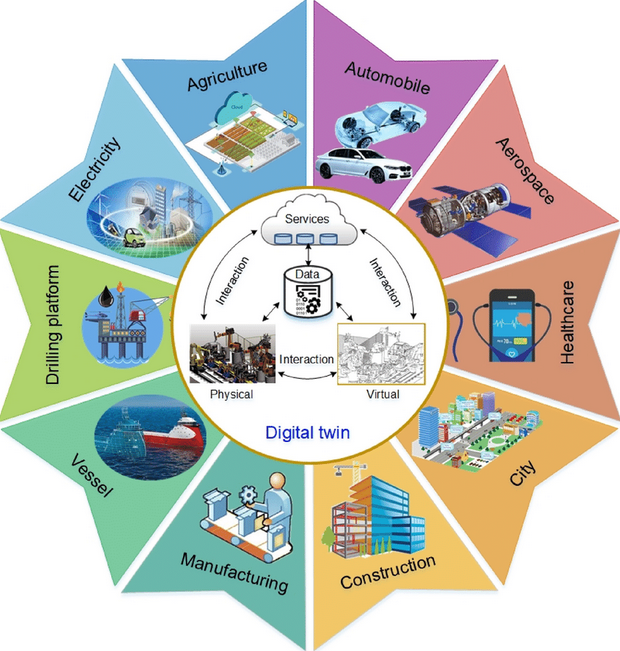

Digital twins have transcended the realm of mere speculation and have become indispensable tools in numerous sectors, spanning from automotive and agriculture to healthcare and manufacturing. At Dualistic, we firmly believe that digital twins are not just futuristic concepts but inevitable components of fully realized digitalization strategies. They represent the pinnacle of digital transformation, offering unparalleled visibility and control over complex systems.

Let’s explore some of the key applications where digital twins are making a significant impact:

Predictive Maintenance: By leveraging historical data and real-time insights, digital twins empower organizations to predict and prevent potential failures in advance. This proactive approach not only optimizes production processes but also fosters a safer and more efficient work environment.

Virtual Sensing: Digital twins enable the measurement of critical quantities in areas where installing physical sensors is impractical or cost-prohibitive. Through sophisticated modeling techniques and existing sensor data, virtual sensing provides valuable information for decision-making without the need for additional hardware.

Virtual Prototyping/Commissioning: With digital twins, companies can simulate and test new components or equipment before they are physically produced. This virtual prototyping allows for interactive testing while mirroring real-world behaviors, including integration with programmable logic controller (PLC) automation controls.

Operational Recalibration: Leveraging insights gleaned from digital twins, organizations can optimize the operations of their systems, fine-tuning processes for maximum efficiency and performance.

Behind the seamless functionality of digital twins lie a set of enabling technologies that drive their development and deployment:

In conclusion, the widespread adoption of digital twins signifies a paradigm shift in how industries approach problem-solving and optimization. By embracing this innovative technology and leveraging its capabilities, organizations can unlock new levels of efficiency, reliability, and agility in an increasingly digital world. As we continue to push the boundaries of innovation, digital twins will undoubtedly remain at the forefront, driving transformative change across diverse sectors.